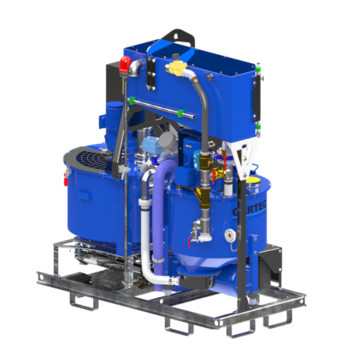

IS-35-EA

Fully automatic

Technical Data / Performance Data

Mixing capacity (20 batches/h) | 3 | m³/h |

Amount of mixing components (automatic operation) | 2 | 1 x liquid 1 x solid |

Effective mixer volume | 150 | l |

Mixing water minimum | 50 | l |

Mixer filling level (bag loading) | 1020 | mm |

Agitator tank volume | 300 | l |

Water Tank volume | 150 | l |

Flow rate stepless adjustable | 20 - 100 | l/min |

Discharge pressure | max. 30 | bar |

Solids grain size | max. 2 | mm |

Pressure connection | VT 1“; Typ 25 | mortar coupling VT 1“,alternatively 1“ IG |

Water connection | Storz C | 1 ½“ standard coupling DIN14307, max.6 bar; or Geka-claw coupling |

Cleaning connection | DN 25 | Geka-claw coupling |

Power connection | CEE-Stecker | 32 A, 5-pole with phase inverter |

Power input | 12,5 | KW |

Voltage | 400 | V; 50 Hz |

Start/Stop signal cement screw | Harting plug | 4-pole |

Transport dimensions approx. | 1,92x0,97x2,15 | m (L x W x H) |

Working dimensions approx. | 2,60x0,97x2,15 | m (L x W x H) |

Weight approx. | 765 | kg |

Application areas:

- Anchor injection

- Grouting

- Cavity filling

- Micro tunnelling

- Ground injection

- Bentonite lubrication

Mixing of:

- Cement slurries

- Anchor grout

- Bentonite slurries

- Filling material for peripheral sealing

- Insulation slurries

- Fly ash slurries

![[Translate to Englisch:] batch mixer colloidal mixer colloidalmixer colloidmixer colloidal mixing technology GERTEC](/fileadmin/_processed_/6/e/csm_colloidalmixer_kolloidalmischer_mixing_technology_GERTEC_fc4f697fb4.png)

![[Translate to Englisch:] hose pump peristaltic pump hose pump peristaltic pump technology GERTEC bored pile special civil engineering tunnel construction jet grouting](/fileadmin/_processed_/e/c/csm_Schlauchpumpe_GERTEC_Peristaltikpumpe_ae16876c4d.png)

![[Translate to Englisch:] robust grout plants colloidal mixer Grouting technology Grout plants Grouting unit GERTEC](/fileadmin/_processed_/b/c/csm_Injektionstechnik_Injektionsanlagen_Injektionsstation_GERTEC_970160c0d4.png)

![[Translate to Englisch:] insolation technology foamed concrete mixer foam generator Foam concrete mixer foamed concrete mixer GERTEC insolation board subfloor levelling](/fileadmin/_processed_/e/2/csm_foam_concrete_GERTEC_89c1edf98f.png)