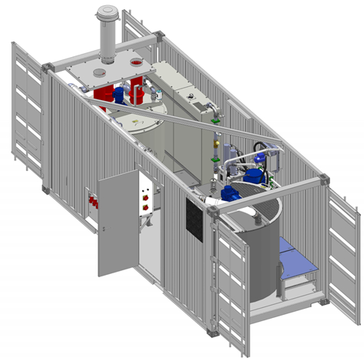

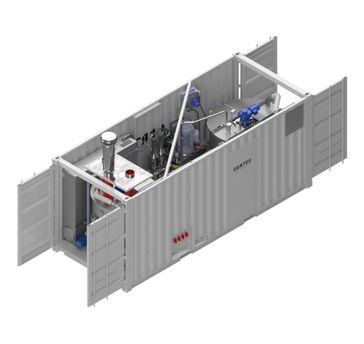

IS-150-EAC

◀

▶

Technical Data /Performance Data

Mixing capacity (15 batches/h) | ca. 22,5 | m3/h |

Effective mixer volume | 1500 | l |

Mixing water minimum | 500 | l |

Water tank volume | 1400 | l |

Buffer tank volume | 3000 | l |

Flow rate water dosing pump | approx. 1000 | l/min |

Flow rate | 0 – 370 | l/min, electrically infinitely adjustable |

Discharge pressure | max. 90 | bar, electrically infinitely adjustable |

Grain size | max. 2 | mm |

Pressure connection | 1 1/2 “ | IG |

Number of mixing components | 3 | 1 liquid 2 solids |

Water connection | 3" | Storz B standard coupling DIN14307 |

Cleaning connection | DN 25 | GEKA claw coupling |

Power connection | 2 x 125 A | terminal block, 5-pole |

Max. power input | approx. 95 | kW |

Voltage | 400 V / 50 Hz | 3~ |

Dimensions | 6,0 x 2,44 x 2,6 | m ( L x B x H) |

Weight | approx. 7600 | kg |

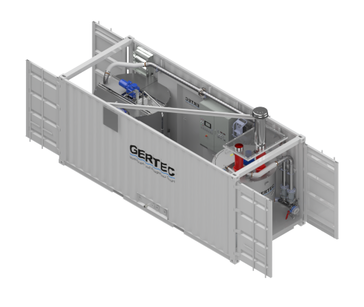

Application areas:

- Anchor injection

- Grouting

- Cavity filling

- Micro tunnelling

- Ground injection

- Bentonite lubrication

Mixing of:

- Cement slurries

- Anchor grout

- Bentonite slurries

- Filling material for peripheral sealing

- Insulation slurries

- Fly-ash slurries

![[Translate to Englisch:] batch mixer colloidal mixer colloidalmixer colloidmixer colloidal mixing technology GERTEC](/fileadmin/_processed_/6/e/csm_colloidalmixer_kolloidalmischer_mixing_technology_GERTEC_fc4f697fb4.png)

![[Translate to Englisch:] hose pump peristaltic pump hose pump peristaltic pump technology GERTEC bored pile special civil engineering tunnel construction jet grouting](/fileadmin/_processed_/e/c/csm_Schlauchpumpe_GERTEC_Peristaltikpumpe_ae16876c4d.png)

![[Translate to Englisch:] robust grout plants colloidal mixer Grouting technology Grout plants Grouting unit GERTEC](/fileadmin/_processed_/b/c/csm_Injektionstechnik_Injektionsanlagen_Injektionsstation_GERTEC_970160c0d4.png)

![[Translate to Englisch:] insolation technology foamed concrete mixer foam generator Foam concrete mixer foamed concrete mixer GERTEC insolation board subfloor levelling](/fileadmin/_processed_/e/2/csm_foam_concrete_GERTEC_89c1edf98f.png)